Top Multi-Function Chuck Type Filling Capping Machine for Efficient Packaging

Agnes

- 0

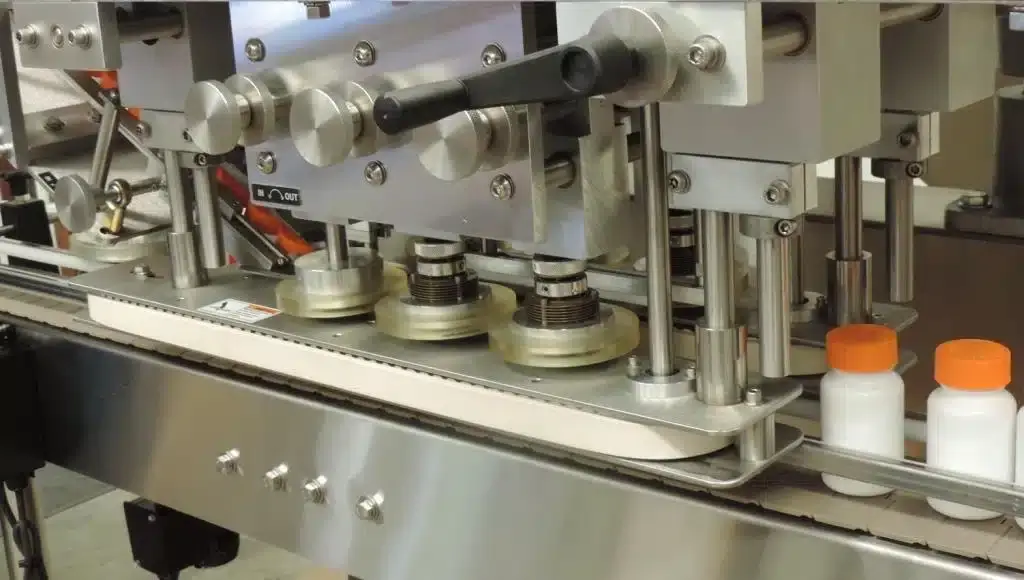

Introduction to Multi-Function Chuck Type Filling Capping Machines

In the fast-paced world of packaging, efficiency and precision are paramount. Enter the multi function chuck type filling capping machine—a game changer Multifunction Chuck Type Filling Capping Machine System for businesses looking to streamline their operations. These machines combine both filling and capping processes into one seamless unit, saving time, reducing labor costs, and enhancing productivity. Whether you’re in food production, pharmaceuticals, or cosmetics, this machinery can transform your packaging line.

Imagine a solution that not only fills bottles with liquids but also securely caps them in a matter of seconds! The versatility of these machines means they can handle various products with ease. If you’re on the hunt for an upgrade to your existing setup or starting fresh with a new venture, understanding what makes these machines tick could be essential for your success.

Let’s dive deeper into why investing in a multi-function chuck-type filling capping machine might just be the best decision for your business!

Benefits of Using a Multi-Function Chuck-Type Filling Capping Machine

Using a multi-function Chuck-type filling capping machine offers numerous advantages for businesses in various industries.

First, efficiency is a key benefit. These machines streamline the packaging process, allowing companies to increase production rates significantly.

Cost-effectiveness follows closely behind. By automating filling and capping tasks, businesses can reduce labor costs while minimizing human error.

Flexibility is another standout feature. These machines can handle different bottle sizes and types, making them ideal for diverse product lines.

Additionally, consistent quality is ensured with precise measurements during both filling and capping processes. This leads to less waste and better compliance with industry standards.

Maintenance is simplified as well; many models are designed for easy cleaning and quick changeovers between products.

Investing in advanced technology enhances the overall brand image by showcasing commitment to efficiency and quality.

Types of Products that Can be Packaged with this Machine

Multifunction Chuck Type Filling Capping Machines are versatile tools designed to accommodate a variety of products. Liquids, including water, juices, and sauces, flow seamlessly through these machines. They ensure precise filling without spills or waste.

Powdered substances also benefit from this technology. Products like spices, flour, or protein powders can be packaged efficiently while maintaining quality and freshness.

Viscous items such as creams and gels find their place too. These machines handle thick formulas with ease, ensuring every container is filled accurately.

Moreover, even granulated products like sugar or coffee grounds can be processed smoothly. This adaptability makes the Multi-Function Chuck Type Filling Capping Machine an essential asset across various industries.

Pharmaceuticals are another significant application area. Bottles filled with liquid medicines or capsules are securely sealed for safety and shelf-life preservation.

Features to Look for in a Multi-Function Chuck-Type Filling Capping Machine

When searching for a Multi-Function Chuck Type Filling Capping Machine, consider its versatility. A machine that can handle various container sizes and shapes adds significant value to your production line.

Look for user-friendly controls. Intuitive interfaces allow operators to adjust settings quickly without extensive training. Efficiency is key in high-paced environments.

Durability matters too. Sturdy materials ensure the machine withstands continuous use while technology maintains precision.

Check for easy maintenance features; machines requiring minimal downtime will keep your operations smooth and cost-effective.

Assess compatibility with different filling mechanisms and capping types. This flexibility enables you to adapt as market demands change, ensuring long-term utility in packaging processes.

Top 5 Multi-Function Chuck-Type Filling Capping Machines on the Market

When searching for the best Multi-Function Chuck Type Filling Capping Machines, several models stand out for their performance and reliability.

First up is the XYZ-1000. Known for its speed and precision, it can handle various bottle sizes seamlessly. Users love its user-friendly interface.

Next is the ABC-FC500. This machine excels in versatility, accommodating different product types from liquids to creams without a hitch. Its robust build ensures durability.

The DEF-220 offers advanced automation features that enhance efficiency significantly. Many businesses appreciate how it minimizes downtime with quick changeovers.

Another noteworthy option is the GHI-MX3000, which boasts an impressive output rate while maintaining high-quality standards in capping and filling processes.

Consider JKL-PRO 400 series machines that focus on energy efficiency without sacrificing productivity. Their compact design fits well into any production space easily.

Case Studies: Success Stories of Businesses Using Multi-Function Chuck-Type Filling Capping Machines

Case studies highlight the transformative impact of multifunction Chuck-type filling capping machines across various industries. For instance, a leading cosmetics brand integrated this machine into their production line to streamline packaging processes. The result? A significant increase in output reduced labor costs, allowing them to allocate resources more effectively.

Another success story comes from a beverage company that faced challenges with inconsistent filling levels and capping errors. After implementing a Multi-Function Chuck-Type Filling Capping Machine, they achieved precise measurements and consistent quality. This upgrade not only improved customer satisfaction but also minimized product waste.

A dietary supplement manufacturer reported similar success after switching to this advanced machinery. Their transition led to enhanced productivity while maintaining strict compliance with health regulations. With greater efficiency, they were able to meet rising demand without compromising on quality or safety.

These examples illustrate how businesses are thriving by adopting cutting-edge technology like the Multi-Function Chuck Type Filling Capping Machine. Each case showcases remarkable improvements in efficiency, consistency, and overall operational performance. As industries continue evolving toward automation and precision engineering, these machines stand out as vital tools for future-ready businesses looking to enhance their packaging capabilities.